Are you sick of how much EVERYTHING has increased regarding just driving from point A to B these days? Gas prices near $4/gal, auto repair rates near $100/hr, high priced parts, registration fees, insurance and inspection costs.

Cars have gotten complex enough that the average person doesn’t feel as though they can work on them. Technology can add to both the purchase price and, when things break, the repair costs. I’m actually thinking I want to go the other way; Anti-technology if you will.

You may have also noticed it’s not unusual to see 70-80% of vehicles on the road have only the driver. Assuming you want an economical 1-passenger commuter vehicle and a bicycle won’t do, your options right now are pretty much limited to a motorcycle or scooter if you want a vehicle for $10K or less. None of these vehicles are very appealing options on cold and/or rainy days.

I’m looking to build an enclosed single-passenger commuter. My plan is to build it with 3-wheels, which classifies it as a motorcycle. This circumvents most of the auto safety requirements that get passed on in the price of the car. After all, what’s the point in crash testing a motorcycle? With proper design a 3-wheeled vehicle can be just as stable as 4-wheeled vehicles.

Unlike a motorcycle, this vehicle will offer –

- Protection from the elements (rain/cold)

- MUCH more crash protection

- Most basic car comforts/features (heater/defroster/vent, windshield wipers, radio, horn, lights, etc.)

Essentially I want to build a 3-wheeled street legal go cart. The drivetrain I’m considering is an 8 hp Honda with an alternator, electric and pull start, and low-oil shutdown. The alternator will run lights and charge the battery. The transmission will be a go-cart type torque converter (CVT). Rough calculations show this vehicle should conservatively get in excess of 100 MPG.

I’m considering a decent sized deep-cycle battery and a 1500W power inverter to run an electric heater. An inverter this size could also run your frig in a power outage. For a heater I’m considering a blow dryer. This gives me the heater and fan in one small inexpensive package.

The gas tank will be a 6-gal outboard engine gas tank. Using the typical outboard engine quick disconnect, it will T into the engine fuel line with an on/off/reserve switch like a motorcycle. The small tank that comes with the engine will be a reserve tank.

EVERYTHING about this vehicle will be designed to be easily worked on with basic tools. To remove the engine it will be 4 bolts, drive chain, throttle cable and the main gas tank line, which will have a quick disconnect. The WHOLE drivetrain (engine & transmission) BRAND NEW will be around $1k via mail order. Ever had your car transmission rebuilt? It’s $1200 minimum AND you have to wait for someone to do it for you.

The plan is to use 10″ mini-bike rims that are around $70/ea, including the brake. These rims complete with tire and tube are about $110/ea mail order. You can’t even put a single tire on some cars for that price. The rims are split rims, meaning you don’t need a tire changer to change a tire or fix a flat. If you can repair a bicycle flat you can fix one on this vehicle.

Steering will likely be handlebars with brake and throttle located on the handlebars. This means someone without the use of their legs could operate one of these vehicles. Still working out how reverse will work, but I’m considering a small electric motor.

The initial design is for a rigid frame to keep things simple and costs down. Subsequent designs may include a suspension. Expecting total vehicle weight to be around 400 lbs not including driver.

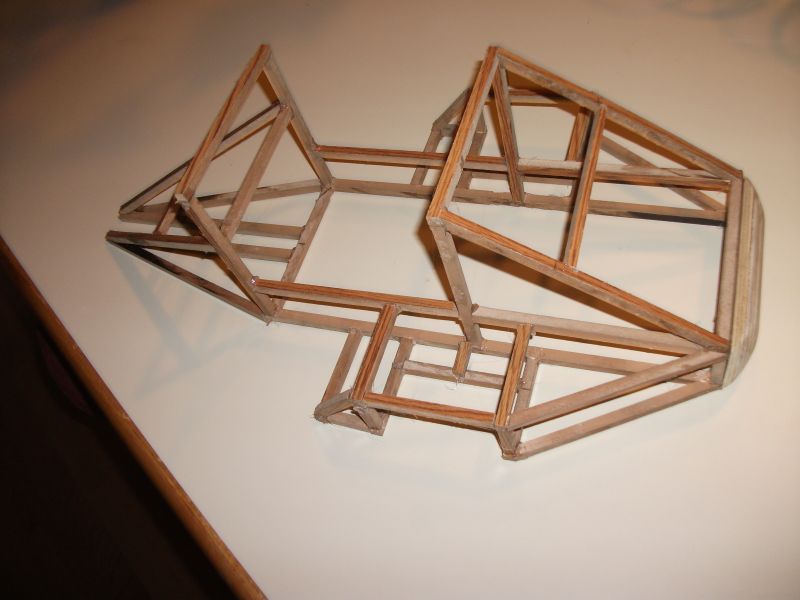

Having spent a lot of time thinking through build details, I built a rough scale model of the frame. Below are pictures of my proposed frame. My intent is to use 1″ square tubing for it to make body fabrication easier. Body panels will just be epoxy painted 1/4″ plywood (luan). Luan is cheap, fairly light, won’t rust and won’t get parking lot dings.

A rough estimate of materials for this is around $3K or less, so sales price on a vehicle like this in the $6k range (factoring in labor to build it) is feasilble. Rough parts cost breakdown is –

- Five full lengths (24’/ea) of 1″ square steel tubing at ~$50/ea. = $250

- Three wheels/tires = $350

- Engine = $700

- Transmission = $300

- Body panels/paint = $200

- Battery and 1500W inverter = $250

The rest of the chassis componets (spindles/axle, steering components, etc.) and other incidentals (lights, heater, speedometer, etc) are approximately $500.

If this works out as a gas-driven vehicle I may try an all electric version. Again, not looking for high-tech. Think “electric golf cart” with higher gearing. Costs for an electric motor/speed controller are close to the proposed gas drivetrain. An electric vehicle will weigh and cost a little more due to batteries, but in the same ballpark price-wise.

Not shown in the picture below is the hard-top canopy, which will hinge from one side and be removable. The plan is to also have a tent type fabric top that can be used if you left the hard-top home and ran into rain.

Note: You may need to click on the picture to get an image with the correct sizing (aspect ratio).

In case you were wondering I used left-over laminate flooring that I ripped into pieces with a table saw for the frame model. The pieces were cut to size and glued together using a hot glue gun, which worked surprisingly well. It’s crude, but helps a lot to visualize how the frame will go together. This is rev 2 of my frame and no doubt there will be more tweaks before I actually build it.

Status update:

On 4/24/12 I posted an update showing the frame minus the swing arm.

As of 5/1/12 I have the swing arm in place and the replacement rim came in and I attached it. Need to order the front spindles, wheels, brakes, and other steering components next.

Here’s an updated picture as of 8/26/12 with the 2 front spindles and wheels on. I have the front disc caliper brake mounts made but have to weld them in place. Next will be the dash and the steering column with the tie rods/ends.

As of 9/29 I started working out the rough dashboard and decided the steering column would be a cross between snowmobile and bicycle. Basically the column will be a pipe with a bicycle goose neck at the top and a quick release for adjusting the handlebars. The column will be supported via a couple pillow block bearing holders. Just a busy time of year so progress is slow. Come winter I hope to have more time.

20 Responses to Single-seat Commuter Vehicle